Our competencies

Your project from A to Z

We offer a comprehensive and integrated approach, covering all stages of your project.

From design to execution, including installation and maintenance, we master every aspect to provide complete and tailored solutions.

With our expertise, we ensure support at every stage to guarantee the success of your projects, from their conception to their operation.

Design

All our plans and calculation notes are created by our Engineering Department (12 engineers and technicians) using CAD systems such as AutoCAD, SolidWorks, and ROBOT, in compliance with current regulations and BIM practices.

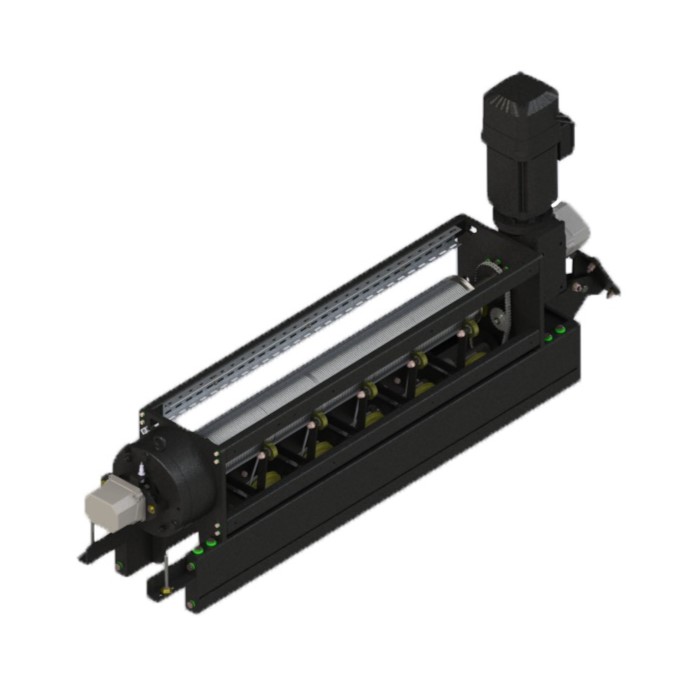

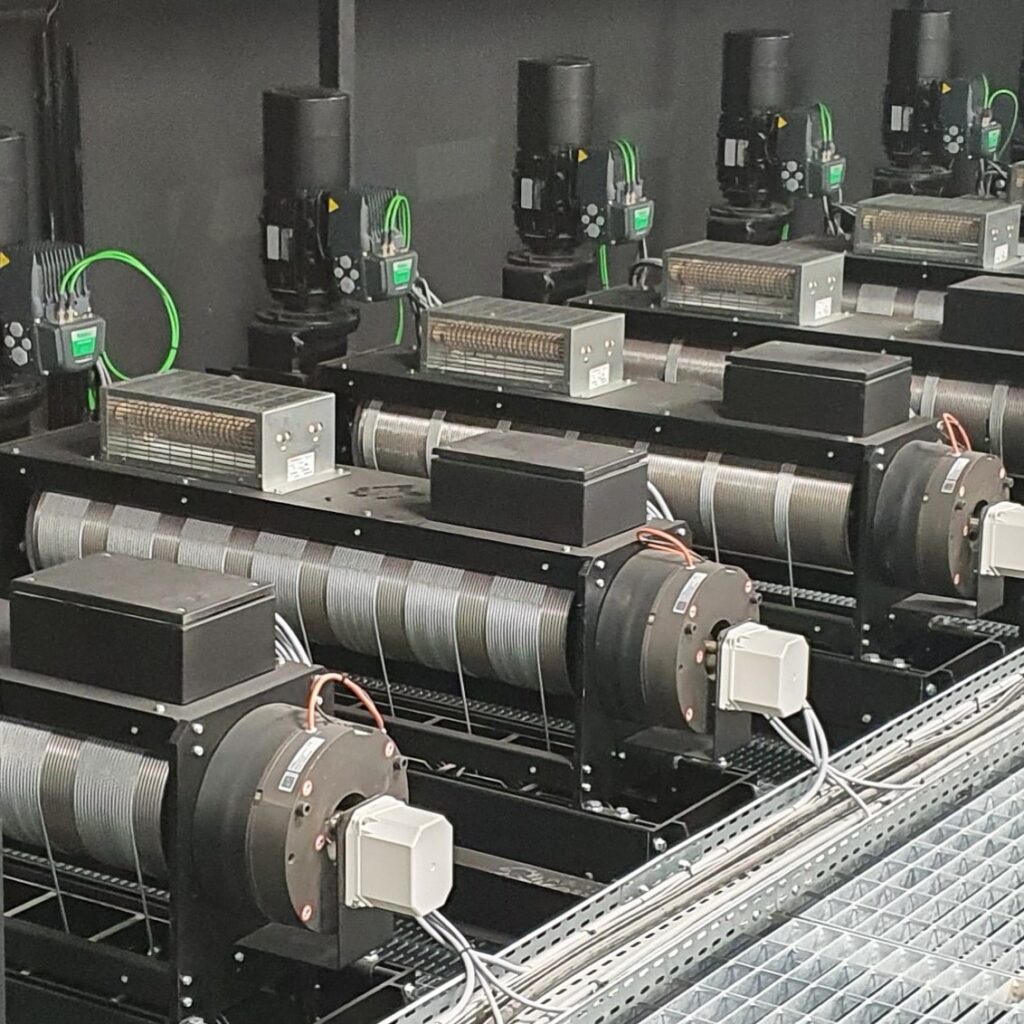

Manufacturing

Our machinery and equipment are assembled and tested in our workshop, before being installed on site. A QAP is set up for large-scale complex projects.

Installation

On-site installation of our stage equipment is carried out by our construction team in compliance with safety and environmental standards.

Commissioning

Upon completion of the assembly, a thorough and rigorous inspection is conducted to ensure the proper functioning and compliance with safety standards of the installation. Training is provided to the end-user team.

Coordination

We work closely with other trades to ensure seamless integration of staging solutions into every project.

Maintenance

Thanks to our team of experienced technicians, we carry out preventive and curative maintenance of stage machinery equipment (in particular lifting equipment) for more than 200 customers in France and Europe every year. Our monitoring helps maintain the performance, reliability and safety of the equipment over time.

As part of this control (examination of the state of preservation and operating tests), we provide and then update a maintenance log for each piece of equipment in compliance with the regulation.

Repairs

Our service technicians are qualified to make adjustments and replace worn, broken or faulty components.

Remote maintenance

Real-time remote reading of parameters on our most recent equipment enables us to make a rapid diagnosis in the event of a fault.

On-call service

We offer on-call service for customers who require it.

Troubleshooting

Thanks to remote maintenance and the geographical coverage provided by our service technicians, we guarantee a high level of responsiveness to meet our customers' needs in the event of a breakdown.

Assistance

We provide assistance to inspection bodies when they carry out checks of our equipment.

Control system

Our stage control systems control the movements of all our motorized machinery in compliance with the requirements of standards NF EN 17206 and NF EN 61508. Our offer is adapted to the different applications encountered, and therefore to the different safety functions required :

- Over-Stage Machinery Control System (UC1-UC2),

- Over-Stage Machinery Control System (UC3-UC4-UC5),

- Under-Stage Machinery Control System (UC-LSL1, UC-LSL2, UC-LSL3, UC-LSL4).

ERGONOMICS – PERFORMANCE – SAFETY are the watchwords of our stage control systems. Numerous functionalities have been developed to meet user needs.